Leveraging AI on Beverage Can Production Lines for Automated Inspections and Enhanced Quality Control

2/08/2023

Project Background

Artificial Intelligence (AI) applications are enhancing the productivity of industrial manufacturing by lowering downtime, reducing costs, and enabling unparalleled real-time decision-making. Visual inspection applications are common scenarios where AI can easily integrate with existing video monitoring, thus eliminating manual footage processing.

Detecting faults, faulty components, and materials handling within the manufacturing process using traditional vision and sensor systems is challenging in many situations. Real-time monitoring through surveillance systems can help prevent problems; however, the active supervising and manual processing required by operation managers is extremely time-consuming and more reactionary than preventative.

To overcome these challenges and reduce overheads, a beverage manufacturer upgraded their surveillance to an AI-based vision-based system for 24/7 automated monitoring.

System Requirements

The manufacturer required a solution that seamlessly integrates with an existing beverage can production lines and camera systems. The solution needed to support high processing speeds to enable real-time computing and AI inferencing at the edge. Additionally, the solution must be flexible and scalable to accommodate future expansion and long-term applicability.

Solution Description

AI has tremendous potential for automated inspections, learning patterns from data, generalizing them, and consistently performing repetitive tasks. When monitoring fast-moving production processes, an AI-based vision system that automates data collection and video analytics becomes indispensable.

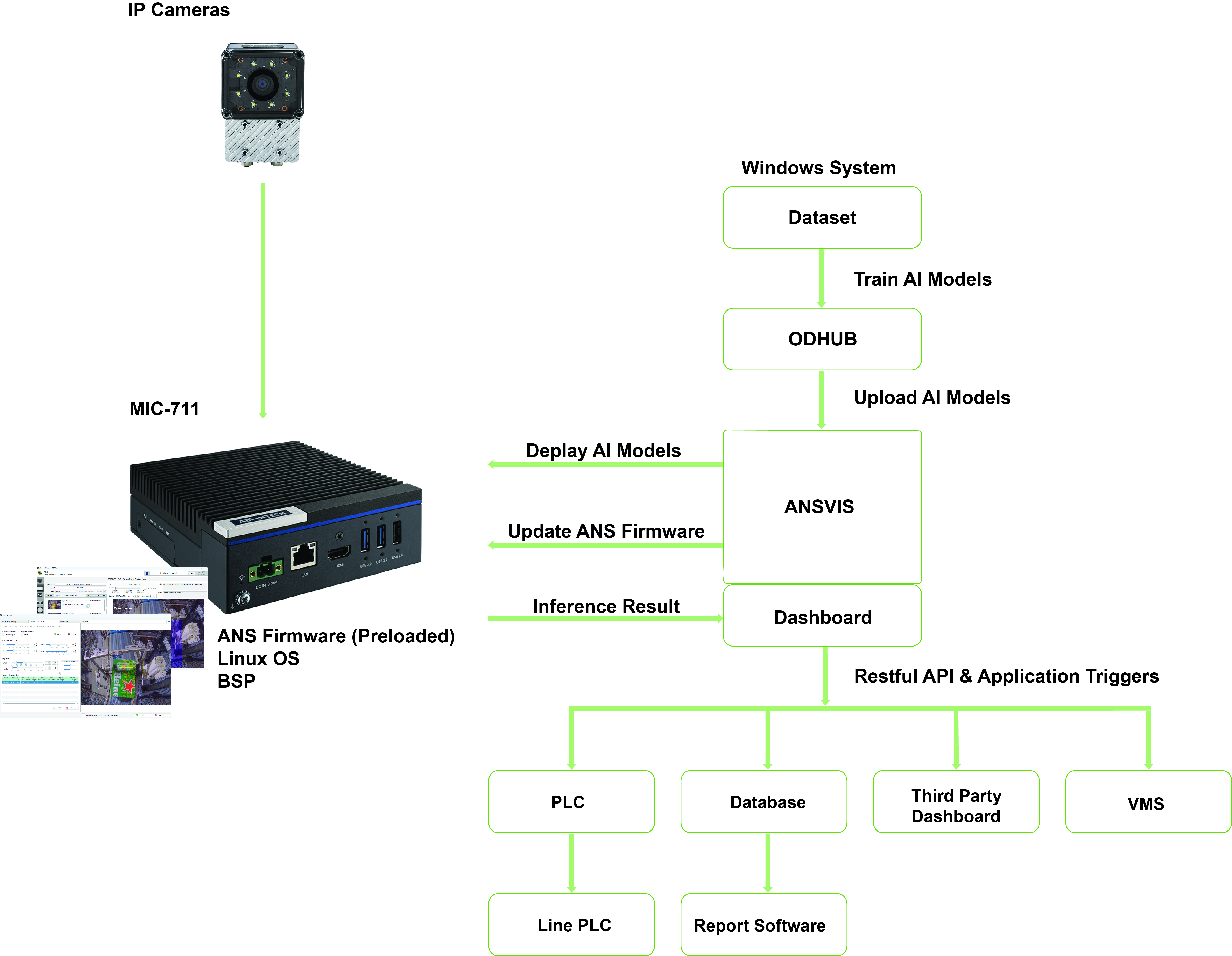

ANSCenter offers an end-to-end visual inspection solution by combining ODHUB and ANSVIS platforms and Advantech's MIC-711-OX fan-less edge AI inference systems. ODHUB serves as an object detection studio, enabling manufacturers to design, train, and validate custom object detection models without complex coding, ultimately facilitating smart manufacturing. Meanwhile, ANSVIS allows model optimization and model deployment in Edge devices effortlessly.

The MIC-711-OX system utilizes the powerful NVIDIA® Jetson Orin™ NX system-on-module to deliver exceptional AI inference performance with 1024-core NVIDIA Ampere GPU and 32 Tensor Cores, achieving up to 100 TOPS.

The solution's unique AI development approach eliminates extensive knowledge requirements, catering to the industrial sector's real-time processing and data security demands.

Data labelling for customised AI model training

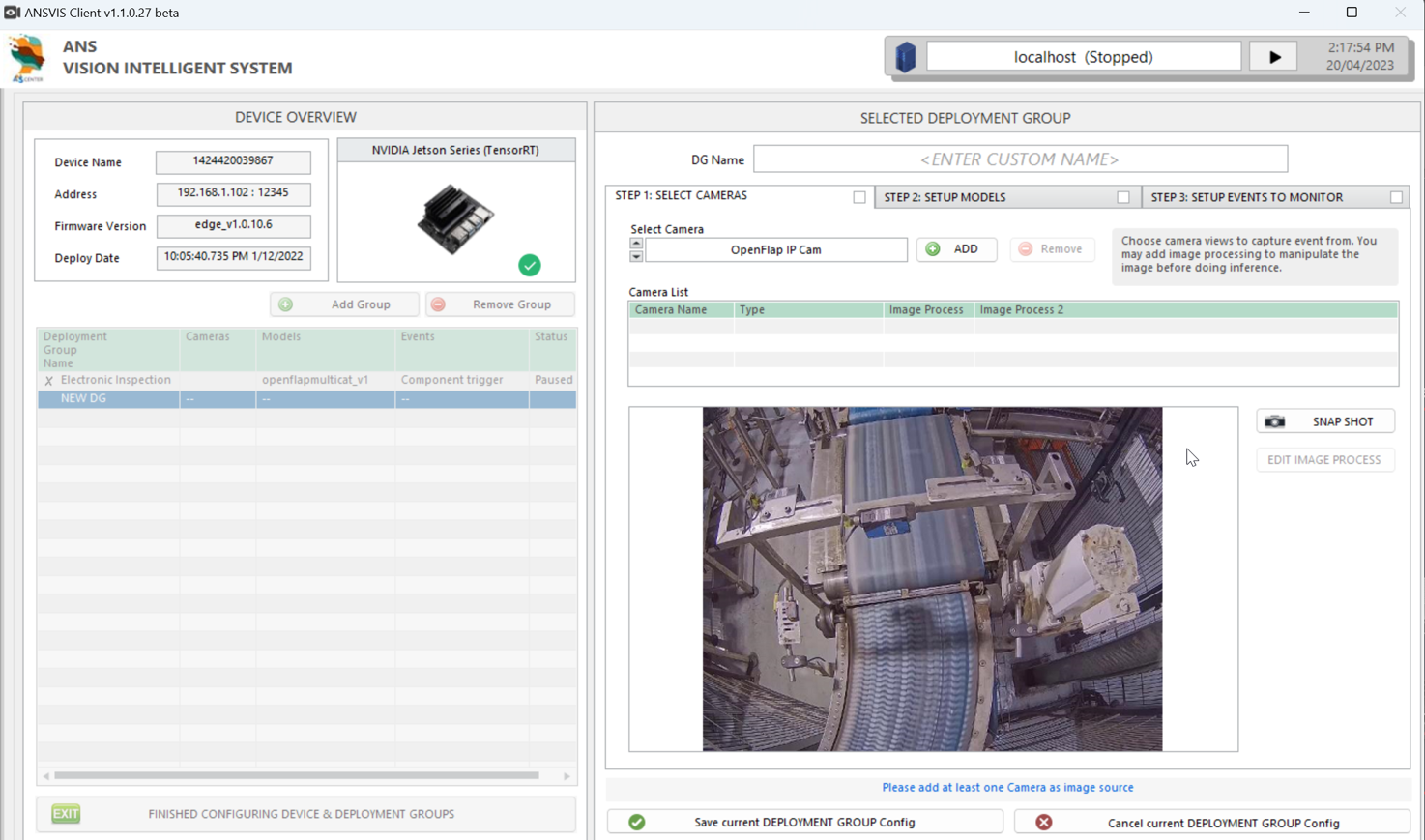

AI task configuration for automated vision inspection in three simple steps

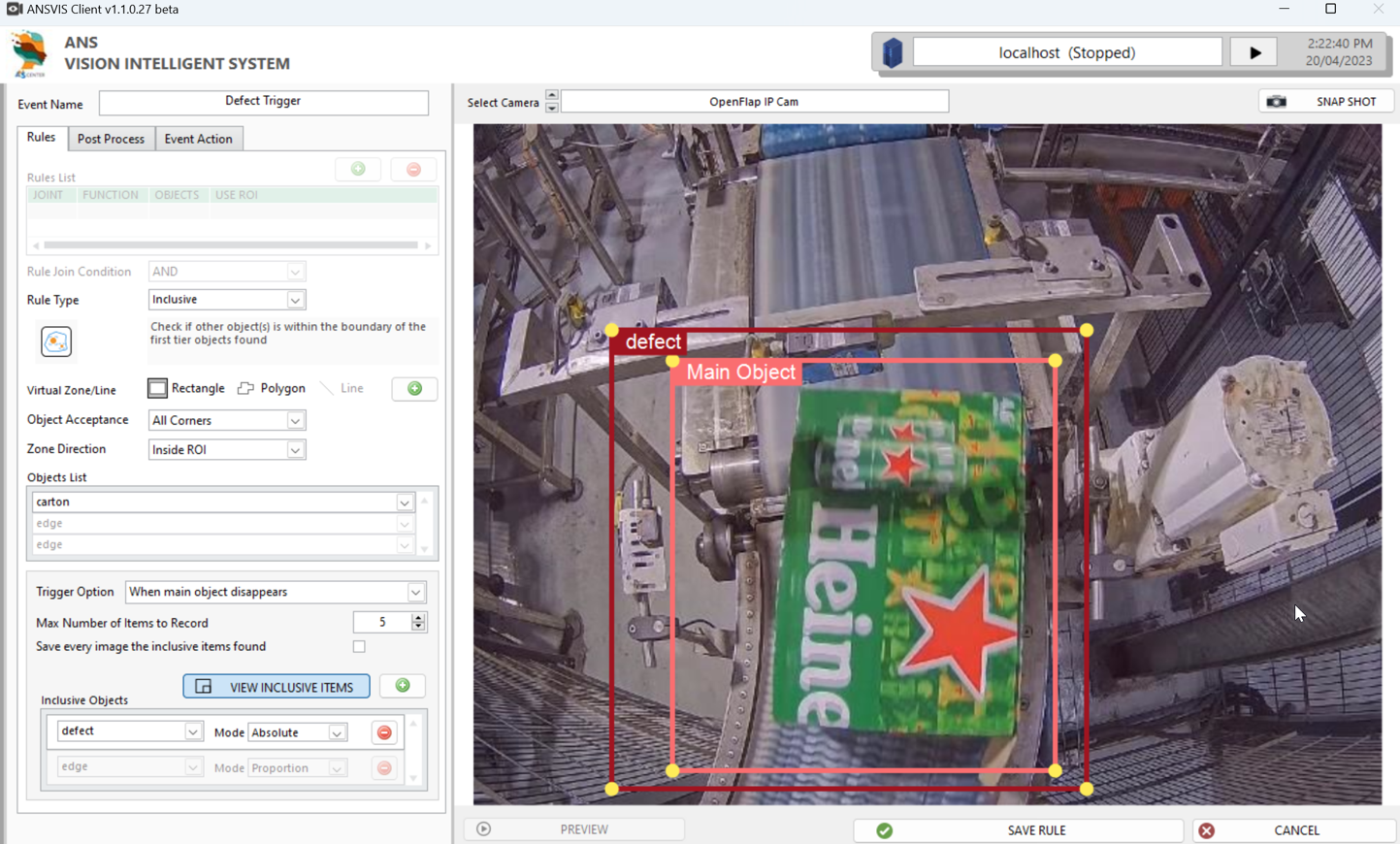

Customised business rule configuration for abnormality detection

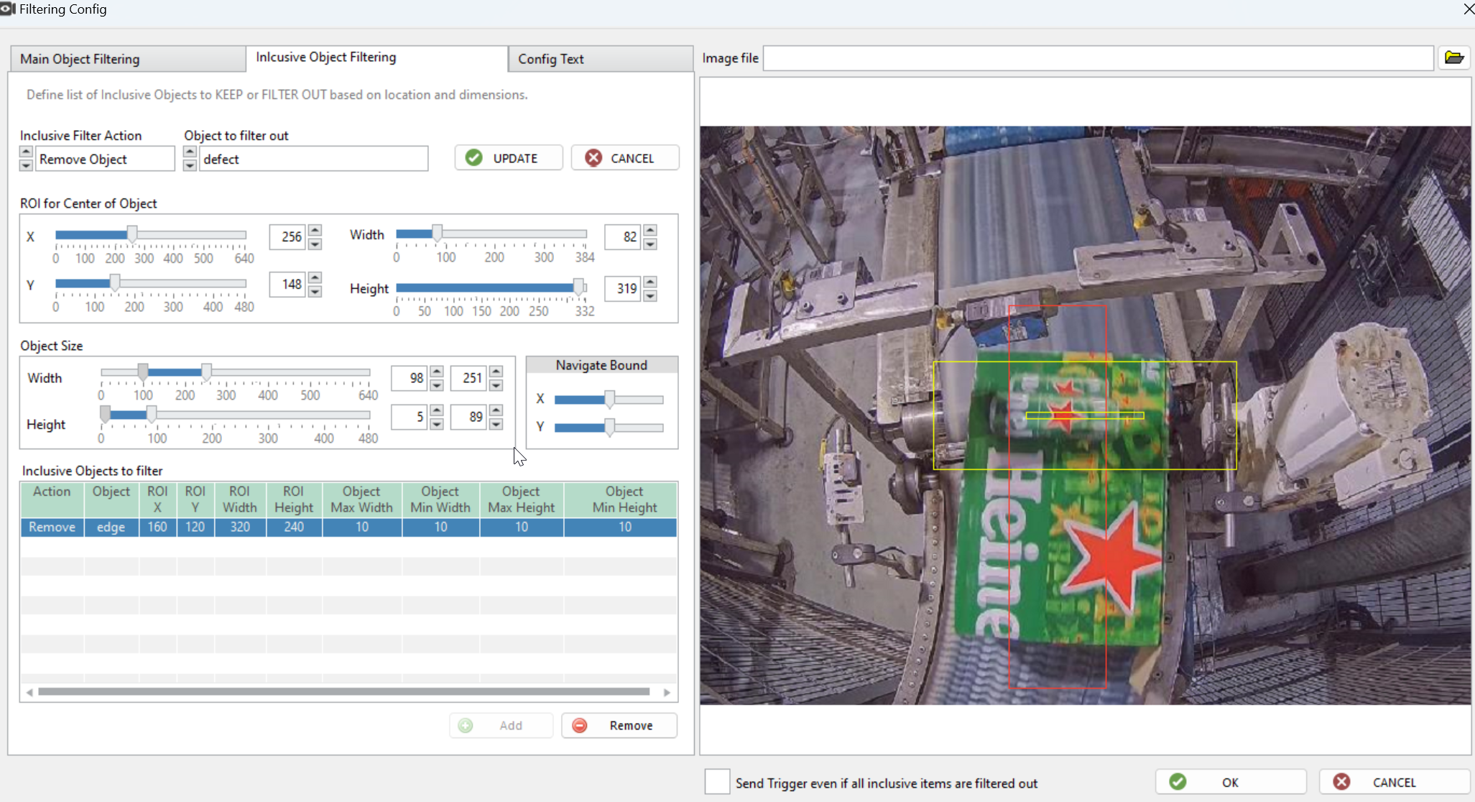

Post processing configuration to enhance defect detection results

Key Solution Features

- Graphical Object Detection Training Tool: Train custom object detection models for complex computer vision tasks.

- AI-Enabled Camera Conversion: Transform existing IP cameras into AI-enabled cameras for intelligent analytics.

- Customized AI Task Design: Support advanced business rules and post-processing plugins for tailored AI task creation.

- Edge Device Deployment: Deploy AI tasks to edge devices for high performance and real-time processing.

- Custom Trigger Options: Enable seamless integration with third-party applications and services, including operator notifications, alerts/alarms/bookmarks sent to video management systems (VMS), hardware control, database saving, and communication with external applications.

- Scalability: Easily expand the system by adding edge devices to meet growing demands.

System Diagram

Benefits

Engineers benefit from a user-friendly GUI with simplified drag-and-drop functionality and model verification features, enabling effortlessly designing and deploying custom object detection models. Mature AI algorithms ensure unified updates and continuous optimization with minimal system downtime.

In case of abnormalities, instant alerts are generated to identify issues for troubleshooting and prevention. The solution offers customizable action triggers, empowering operators to adjust response actions based on specific requirements. Additionally, the high flexibility of the AI vision solution makes it easily accessible, affordable, and scalable, resulting in significant reductions in maintenance and upgrade costs.

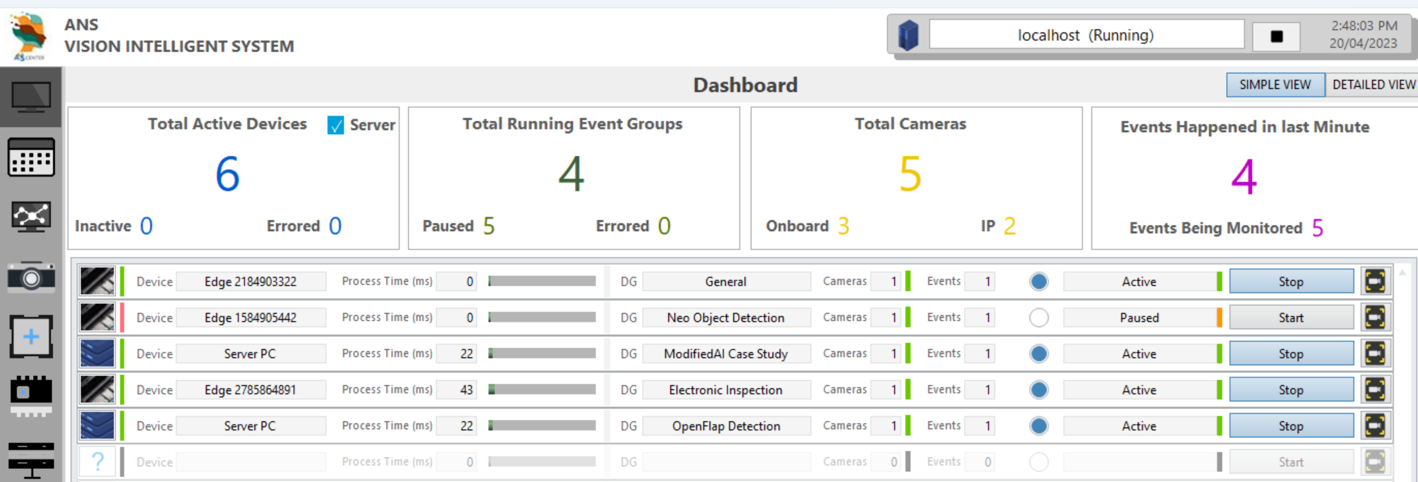

Dashboard to monitor entire system’s status.

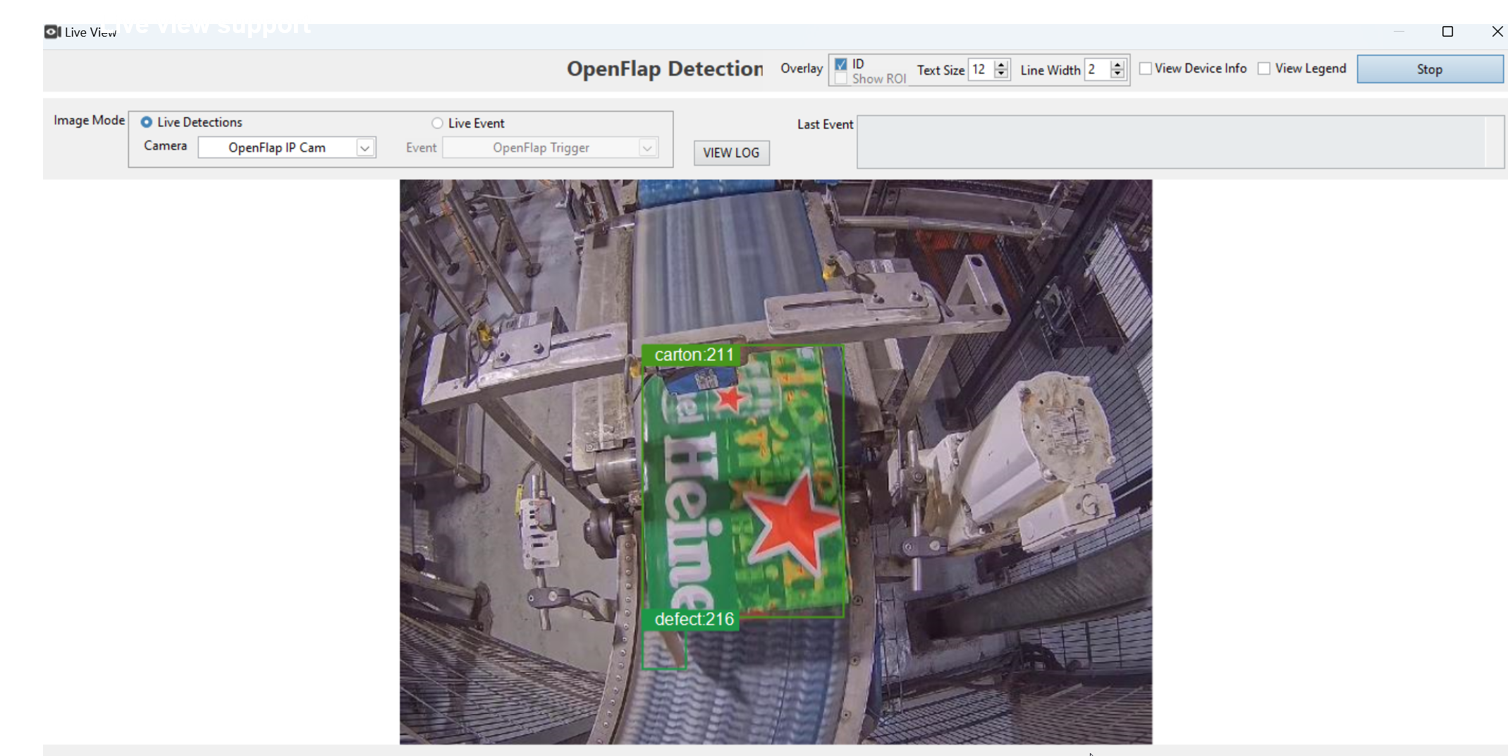

Event Live View

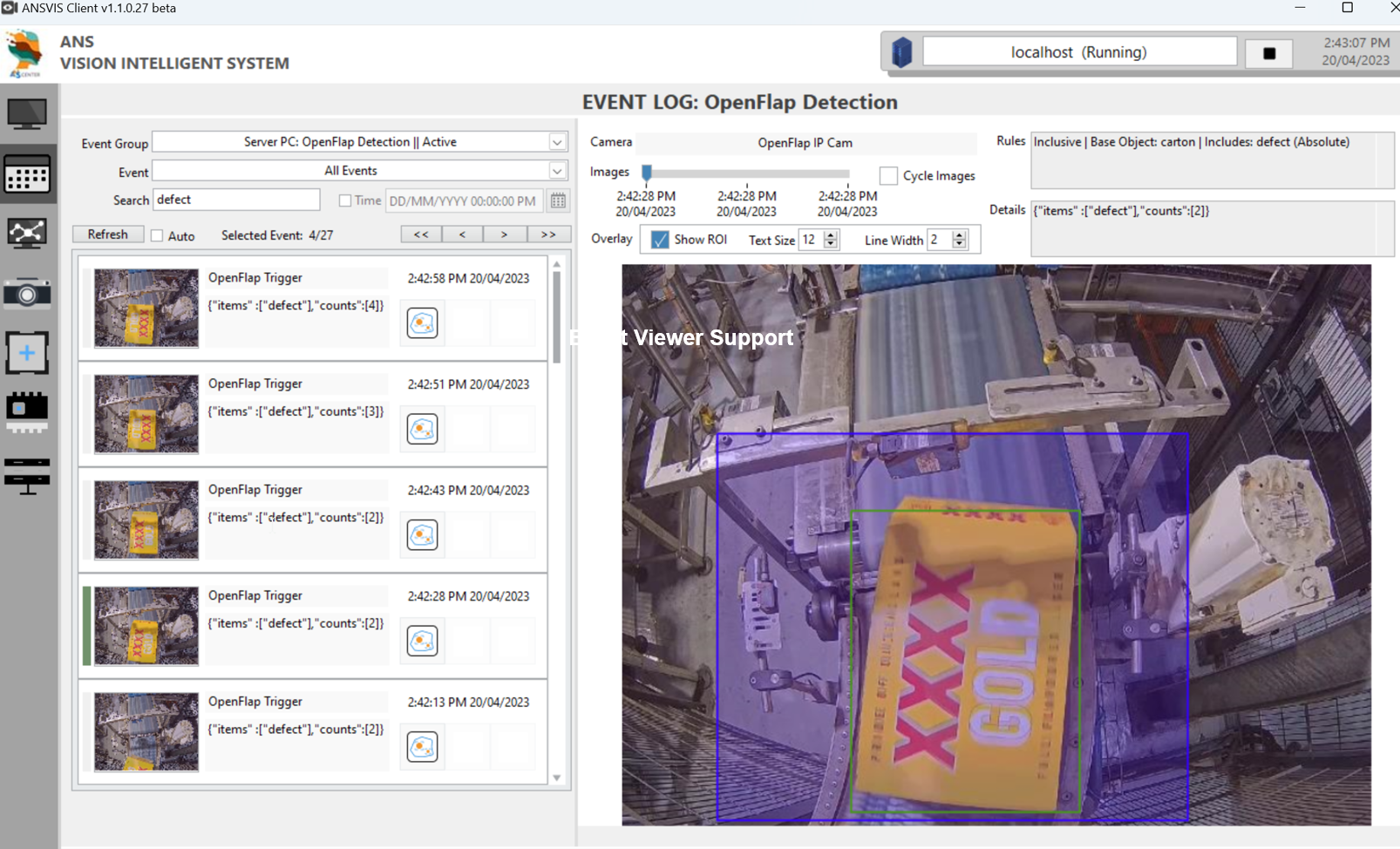

Event log to review and export results

- Graphical AI Development Platforms: Create AI models without the need for complex programming using intuitive graphical interfaces.

- Utilize Powerful GPUs and Edge AI Solutions: Harness the capabilities of high-performance GPUs and Edge AI solutions to achieve optimal real-time processing.

- Rapid Deployment of AI Models: Quickly deploy AI models using a variety of compatible APIs and plugins, streamlining the implementation process.

- Compliance and Security: Ensure adherence to industry compliance standards and minimize security risks by keeping data processing in-house.

- Advanced AI Architecture and User-Friendly GUI: Benefit from advanced AI architecture and a drag-and-drop graphical user interface (GUI) for easy configuration and expansion across diverse usage scenarios.

-25/MIC-711-ON_0320230517094751.jpg)

-25/MIC-710AI_Front-left_P-(1)20240126143138.png)

-25/未命名20230711093456.png)