The collaboration between Tianjin Chinetek Barcode and Advantech helped Danfoss become a benchmark enterprise for factory digitization

8/04/2021

2019 World Economic Forum “Global Lighthouse Network”: Danfoss (Tianjin)

Lighthouses are usually located by coasts, ports or riversides, used to guide the direction of ships; therefore, the lighthouse also has the meaning of being an “index”. With the continuous trend of smart manufacturing transformation, the World Economic Forum (WEF) began to announce the “Global Lighthouse Network” each year starting in 2018, selecting the most representative manufacturers with the best results in applying digitization and intellectualization technologies.

In the 2019 World Economic Forum, the “Global Lighthouse Network” welcomed seven new members, and Danfoss (Tianjin) Limited (hereinafter referred to as Danfoss (Tianjin)) was among one of them. The evaluation that the WEF gave this factory was: Danfoss (Tianjin) improved their quality control system successfully by applying digital tools such as fully digital traceability systems, smart sensors, visual inspections and automatic monitoring systems. This increased their labor productivity by 30% and reduced customer complaints by 57% within two years.

Century-old Danish brand becomes world’s leading enterprise

Danfoss, the largest multinational manufacturing company in Denmark, was established in 1933. After almost a century of growing and evolving, Danfoss has become a leading global refrigeration enterprise that provides air conditioning control, heating, transmission, and power system solutions. As a wholly-owned subsidiary of Danfoss in China, Danfoss (Tianjin) Limited was established in 2003 and mainly manufactures various types of industrial compressors; many major home appliance companies are important customers of Danfoss (Tianjin), including GREE and Midea.

When Danfoss (Tianjin) stood out from over 1,000 factories worldwide and was chosen as one of the seven new members of the Global Lighthouse Network, its success quickly gained the attention of the domestic manufacturing industry. Others hoped to find the light from it that could help lead them to success with digital transformation.

Eliminating data opacity! Building a fully digital traceability system using quality control as the core

Danfoss (Tianjin) was also troubled by problems such as data opacity before 2014. All of the on-site data in the workshops had to be recorded manually and resulted in delays for the production material summary table; a unified data management system was also missing to trace production information. There was no statistical data for decision-making and improvement tracking. Therefore, the production department could not receive real-time information on the operation statuses of the machines and work orders, and equipment could not be regulated flexibly to work with frequently changed production schedules.

Faced with rigorous quality control challenges, the managerial levels of Danfoss (Tianjin) performed in-depth evaluations in 2014 and decided to begin digitization upgrades using quality control as the core. The upgrades focused on the pain points and difficulties during the quality control process; fully digital traceability systems and process control modules were developed, and the quality control management systems were optimized continuously. As a long-term partner of Danfoss (Tianjin), “Tianjin Chinetek Barcode,” which specializes in quality control and tracking, was deeply involved in the digitization upgrades of Danfoss (Tianjin).

The backstage driving force of quality control and digital tracking: Tianjin Chinetek Barcode Technology Co., Ltd.

Tianjin Chinetek Barcode Technology Co., Ltd. was established in 1994; it is committed to developing automatic identification technologies such as barcodes, RFID and magnetic cards, and product promotions and applications. In the past decade, it also focused on the system integration field. The Tianjin Chinetek Barcode systems range from quality tracing, quality control, obtaining of production information, materials and equipment management, etc. for manufacturing, providing complete informatization solutions for various types of manufacturing enterprises.

According to the introduction by the company's general manager, Gui-yan Zhao, the two enterprises have built close business partnerships since Danfoss (Tianjin) was established in 2007. Tianjin Chinetek Barcode not only participated in the construction of the computers, networks, and barcode equipment systems during the initial stage of factory establishment of Danfoss (Tianjin), it also helped Danfoss (Tianjin) realize their visions of on-site operations management, quality control and equipment management systems during the digitization upgrade stage.

Broke industry deadlocks: Build digitized factories and launched transparent information management

Challenges of continuous development for manufacturing in recent years include: stagnated productivity, increased customization needs, gradual aging of the labor force and pressure from adjusting industrial structures. The multiple challenges listed above forced enterprises to accelerate their digital transformation.

Faced with the continually increasing tempo of market competition, the continually reducing production cycle of products, and the continually increasing demands of product quality, creating digital systems that can trace all processes of products and control the quality during the processes to realize factory data transparency is the best choice for Danfoss (Tianjin). It will improve their quality, increase their performance, and reduce their cost.

“As a partner of Danfoss (Tianjin), we learned the production processes of the factory comprehensively and had an in-depth understanding of the application pain points that might be caused due to data opacity. We have accumulated years of system integration experiences that made us capable of solving the problems described above, and this is one of the key factors why Danfoss (Tianjin) chose us to participate in the implementation,” said Gui-yan Zhao.

Dual consideration from the technical aspect and business aspect: Deployment in stages provides maximum benefits

After evaluating the current condition of the quality control and requirements of Danfoss (Tianjin) appropriately, Tianjin Chinetek Barcode proposed the suggestion of “staged deployment” based on their own experiences.

From the technical aspect, deploying the systems of the entire factory in stages continuously can ensure a flexible implementation process while maintaining interactivity between the subsystems, reducing project risks and shortening the implementation period. From the business aspect, staged deployment can generate a higher return on investment.

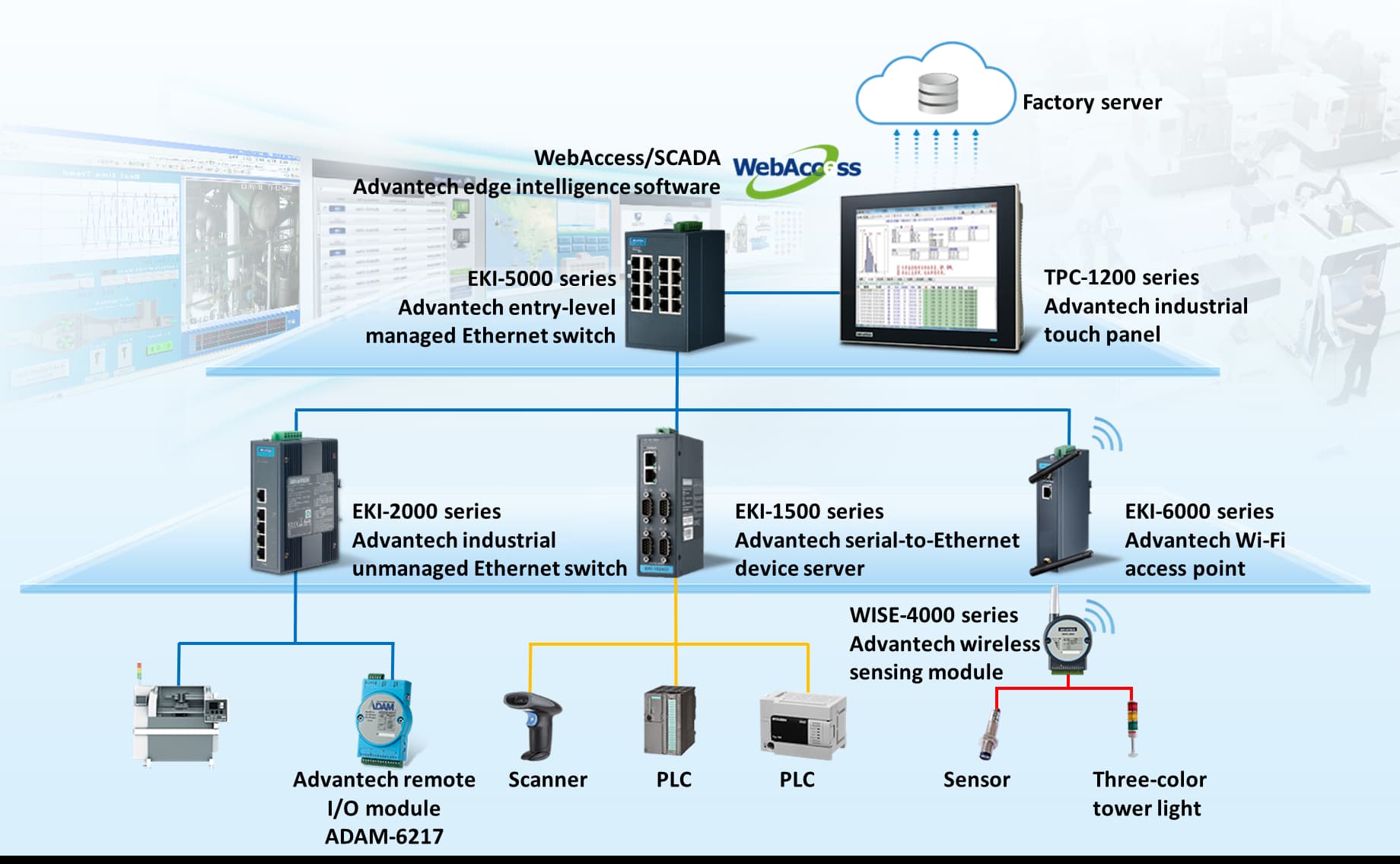

Danfoss (Tianjin) finally decided to adopt the staged deployment suggestion after full consideration and began executing the project in stages in 2014. As an important implementer for constructing the quality control system, Tianjin Chinetek Barcode was responsible for three major tasks: data collection, network transmission, and smart management. With the help of the digitized factory information management solution of Advantech data collection, hardware I/O modules were used to collect the information of on-site equipment, external transmissions were made using Ethernet switches and Wi-Fi APs, and visualized management was completed using industrial tablet computers equipped with the Advantech software WebAccess.

Designed specifically for digitized factory information management, Advantech provides golden product combinations

For the different functional features of the industrial field equipment, Tianjin Chinetek Barcode chose Advantech’s serial server EKI-1524, the ADAM I/O module and the WISE wireless sensor module to be responsible for data collection, EKI-2000 & 5000 series Ethernet switches and the EKI-6000 series Wi-Fi AP to be responsible for data transmission, and TPC industrial tablet computers equipped with the WebAccess software to realize visualized remote management.

EKI-1500 Series

Serial Device Server

Equipped with four RS-232/422/485 serial ports and two Ethernet ports, used to connect barcode printers, barcode scanners, PLC, torque gun and other on-site serial equipment. After data of the various process requirements are collected, the data is transmitted externally through the Ethernet.

WISE-4000 Series

Wireless Sensor Module

EKI-6333 Series

Wi-Fi Access Point

EKI-2000 Series

Unmanaged Ethernet Switch

Used as the bridge for Ethernet communication; it receives the on-site data transmitted by the EKI-1524 serial server through Ethernet and forwards the data to a specific managed switch.

EKI-5000 Series

Entry-level Managed Ethernet Switch

It receives the on-site operation information sent from various equipment to improve the overall Ethernet architecture's efficiency and forwards the data to specific industrial computers for further data processing and analysis.

TPC-1200

Industrial Tablet Computer

A touch control tablet computer with LCD display for personnel to operate on-site; it is equipped with graphical control software to assemble and calculate scattered data into meaningful charts. (There are also the TPC-XX81/82 series flat screen TFT touch screen computers available for selection)

WebAccess/SCADA

Browser-based SCADA Software

Realizes visualized management of equipment operation information and improves productivity significantly.

Danfoss x Tianjin Chinetek Barcode x Advantech: Cross-industry cooperation creating a digital transformation

As a company with over 26 years of experience in automatic identification technology and product development, 10 years of experience in system integration services, Tianjin Chinetek Barcode not only owns products and technologies that lead the industry, it can also fully understand the pain points and needs of enterprises; it completes digitized factory projects by combining its two major strengths: technology and experience. Danfoss (Tianjin) is the best model for the digital transformation of enterprises.

As a partner for many years, Tianjin Chinetek Barcode fully understood the digitization upgrade needs of Danfoss (Tianjin); as a VIP system integration partner of Advantech WISE-PaaS, Tianjin Chinetek Barcode fully understands the technical products and solution advantages of Advantech. Its rich industry experience allowed Tianjin Chinetek Barcode to stand out and flexibly match the best software and hardware products and solutions of Advantech according to the digitization upgrade needs of Danfoss (Tianjin); not only is great stability and high immediacy guaranteed after system implementation, the equipped features such as strong environmental adaptability etc., also allow customers to easily perform digital upgrades in the future through modular execution methods.

As stated by the plant manager of Danfoss (Tianjin), Rui-xing Zhang: “Connecting the statistical process control system to the processing lines using fully digital tracing systems realized higher-precision real-time controls. Each workstation is connected through an interlocking system, ensuring the product qualification rate at each production stage. For example, the visual inspection system can ensure the highest product quality; quick responses can be made for any quality warnings or problems.”

Currently, the product defect rate of Danfoss (Tianjin) has always been kept under fifty PPM; the importing of the quality control and tracing systems further deepened the digital application of Danfoss (Tianjin) and laid a solid foundation for factory intellectualization.

- For more product inquiry, please contact iiot.tech@advantech.com

- Advantech experts will be providing you with dedicated support soon!

/EKI-1526_S20140604152129.jpg)

/EKI-1521_Front _S20180627144304.jpg)

/EKI-2525_02_S20160518163803.png)

/EKI-2525M_S20181106162411.png)